What

is Automotive Warranty Management?

Warranty management is the process

of handling vehicle repair claims when a car part fails within a

specific period. A well-managed warranty system helps:

✔ Reduce costs for automakers

and suppliers.

✔ Improve customer satisfaction

by resolving issues quickly.

✔ Prevent future problems by

identifying defects early.Auto Genius provides OEMs an advanced warranty management software to manage their automotive warranties effectively.

📌 Example: Imagine

you buy a new car, and after six months, the air conditioning stops working. If

the car is still under warranty, the dealer will repair or replace the faulty

part for free. But if warranty claims are not handled properly, delays

and confusion can frustrate customers.

Who

is Responsible for the Warranty Process?

Many people are involved in handling

warranty claims:

1️ Car Manufacturer (OEM - Original Equipment Manufacturer)

- Creates warranty policies and guidelines.

- Works with suppliers and dealers to process claims.

- Ensures quality control in car manufacturing.

2️ Suppliers (Parts Manufacturers)

- Provide high-quality parts and components for

vehicles.

- Help investigate why a part failed.

- Assist in reducing warranty claims by improving their

products.

3️ Dealers (Car Showrooms & Service Centers)

- First contact point

for customers facing problems.

- Diagnose the issue and decide whether the repair falls

under warranty.

- Communicate with manufacturers and suppliers to fix the

problem.

How

to Handle Warranty Claims Efficiently?

When a part fails, the company must

follow a clear and structured process to fix it. Key best practices

include:

✔

Documented Warranty Policies – Both internal teams and suppliers should

have a step-by-step guide on how to handle claims.

✔

Regular Training for Dealers & Suppliers – Proper training ensures

that warranty claims are processed correctly and fairly.

✔

Easy Access to Warranty Data – Companies should have online portals

where suppliers can see warranty claim records. This helps in faster

investigations.

🔍

Example: If multiple cars have the same brake issue, an online

system will help identify the problem faster. The supplier can then analyze

and improve the brake design to prevent future failures

Importance

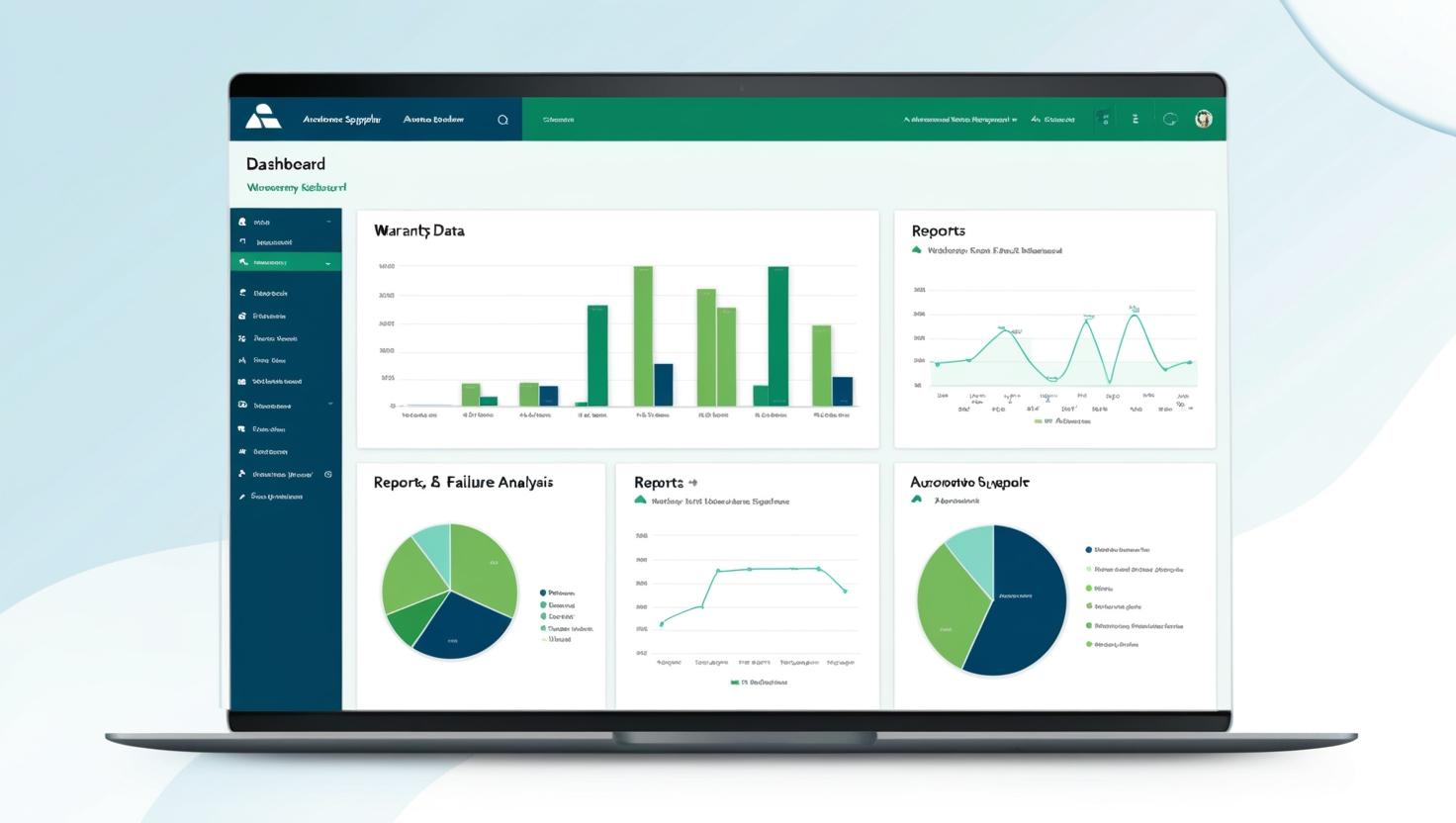

of Warranty Data and Online Portals

Manufacturers and suppliers need detailed

data to investigate warranty claims properly. This data includes:

📌 Dealer Reports – What problem the

customer reported, what was repaired, and whether the issue was solved.

📌 Vehicle Data – Information collected from car sensors

and onboard diagnostic systems.

📌 Warranty History – Records of past repairs and similar issues

in other vehicles.

💡 Best Practice:

Automakers should create easy-to-use online portals where suppliers can

check warranty data, download reports, and analyze failure patterns.

How

to Return and Analyze Defective Parts?

To truly understand why a part

failed, companies must examine the defective component. But not all parts

can be sent back for review due to high costs. Instead, manufacturers

should:

✔

Decide which parts to return based on the issue type.

✔ Hold monthly review meetings

to check faulty parts.

✔ Use video meetings so that

remote teams can also inspect defects.

📌 Example: If fuel

pumps in a certain model are failing too often, collecting some defective

pumps from dealerships will help suppliers find out if the issue is due to poor

material quality or incorrect installation.

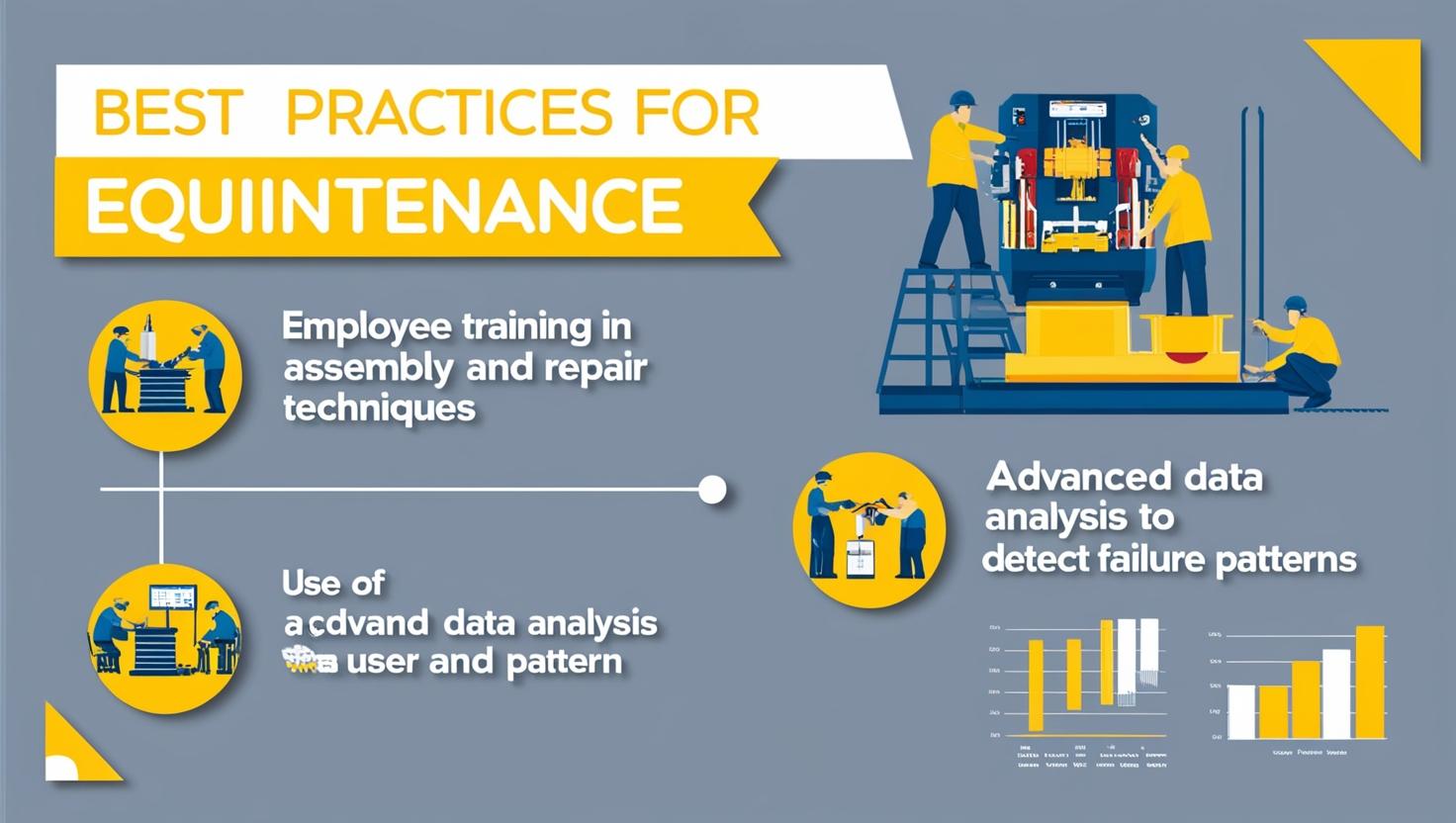

Reducing

Warranty Costs: What Are the Main Issues?

Warranty claims cost millions of

dollars each year. The biggest cost drivers are:

1️ Manufacturing Mistakes – If a factory assembles

parts incorrectly, they may fail early.

2️ Wrong Repairs by Dealers – Sometimes, the real issue is not fixed,

causing repeat claims.

3️ "No Trouble Found" (NTF) Cases – When a car is brought for

repair, but technicians can’t find anything wrong, the issue remains

unsolved.

💡 Best Practice:

✔ Train employees in correct

assembly and repair techniques.

✔ Use advanced data analysis

to detect patterns in failures.

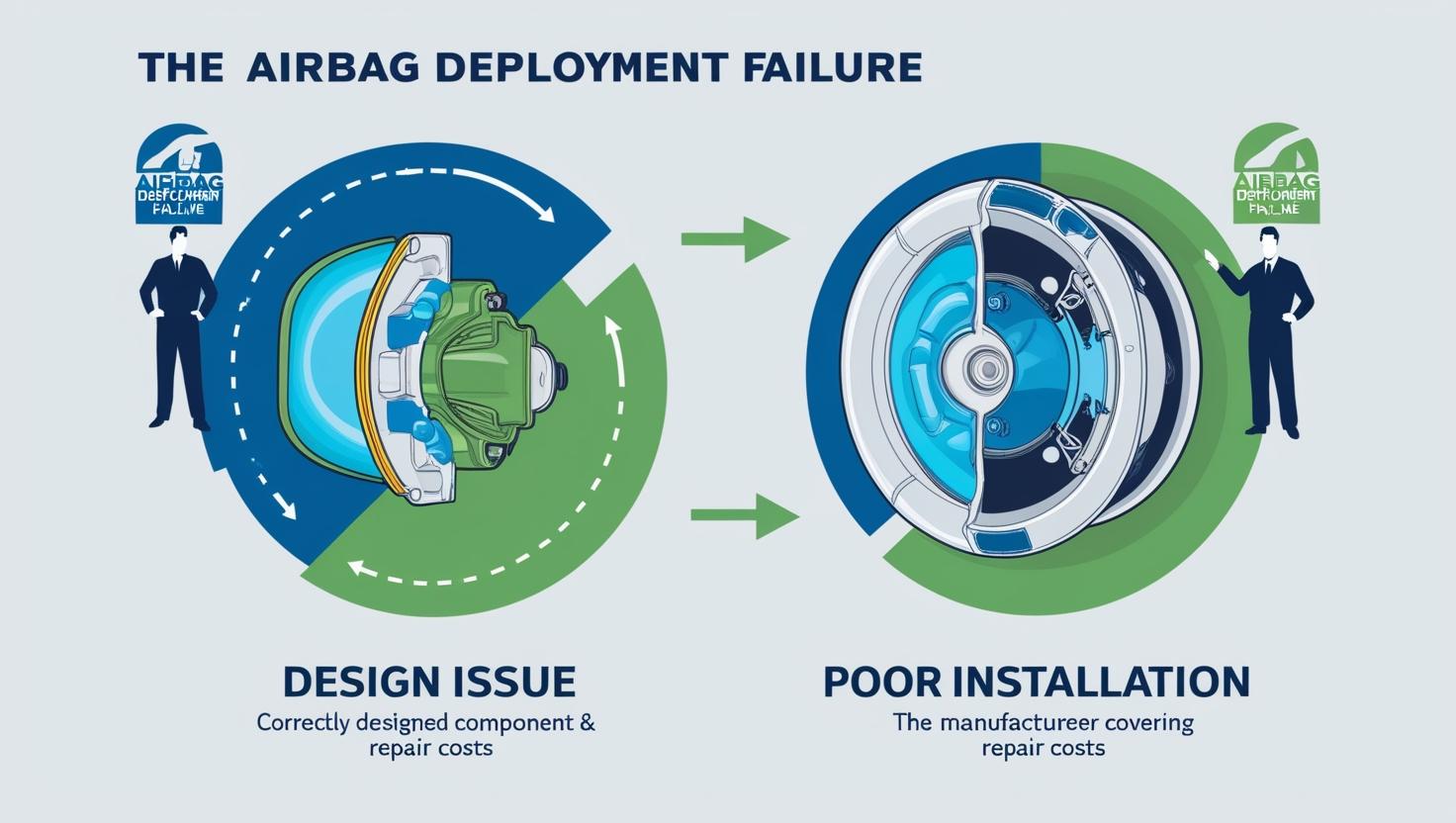

What

is a Fair Cost Recovery System?

When a part fails under warranty, who

should pay for the repair?

- If a supplier made a faulty part, they should cover

the costs.

- If a manufacturer installed it incorrectly, they

should pay.

- If the problem is unclear, both parties should investigate

and share the costs fairly.

📌 Best Practice: A clear,

documented process should be in place to decide who is responsible

for each claim.

🚗 Example: If an

airbag fails due to a design issue, the supplier may cover the repair

cost. But if it fails due to poor installation at the factory, the

manufacturer should pay.

How

Technology Can Improve Warranty Management?

With modern technology, companies

can prevent warranty issues before they happen:

📊 Data Analytics –

Helps detect failure patterns before a problem becomes widespread.

📡 Car Sensors & Telematics – Collects real-time data about

how a car is performing.

🛠 Artificial Intelligence (AI) – Helps analyze customer

complaints and identify common defects.

✅ Example:

A car manufacturer notices that engine temperature sensors in a

certain model fail after 50,000 miles. By analyzing data from multiple

vehicles, they can recall and replace sensors before a serious issue

occurs.

Building

Strong Relationships Between Manufacturers, Suppliers, and Dealers

Many warranty issues happen because dealers,

manufacturers, and suppliers don’t communicate properly. To improve

relationships:

✔

Encourage dealers to share more details when submitting claims.

✔ Give suppliers full access

to warranty data so they can investigate issues faster.

✔ Allow dealers to contact

suppliers directly for technical support.

📌

Example: A car dealership struggles to repair a complicated electronic

braking system. Instead of waiting for slow responses from the

manufacturer, they call the supplier directly for help.

What

Happens in the Future?

As vehicles become more advanced,

warranty management will become more complex.

🚗 Electric Vehicles (EVs)

have different failure patterns compared to gasoline cars.

🔌 Self-driving technology will need new warranty rules for software

failures.

📡 Subscription-based car models (where people don’t own cars but

rent them monthly) will create new challenges in warranty policies.

The best

companies will be those that create flexible and data-driven

warranty systems to adapt to these future challenges.

This guide provides a clear,

step-by-step approach to managing automotive warranties effectively. By

using data, technology, and collaboration, manufacturers, suppliers, and

dealers can reduce costs, prevent failures, and keep customers happy.